- Tel : +86-0311-85236281

- E-mail : sales@wirecloths.com sales4@wirecloths.com

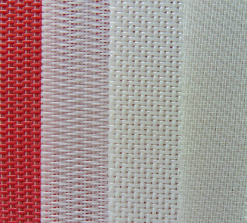

The steps for making a Polyester Molding Mesh are as follows:

(1) Polyester bottle pulverization - using a polyester bottle to be placed in a plastic pulverizer, which is pulverized into a polyester bottle piece;

(2) High-temperature washing - the polyester bottle is placed in a high-temperature washing machine for high-temperature cleaning to remove microbial parasites;

(3) Drying and drying - drying and dehydrating the polyester bottle pieces using a centrifugal drying device;

(4) Mixing--put 85-92% polyester bottle, 1% anti-aging agent, 2% reinforcing agent, 5%-12% flame retardant into the mixer, balance and stir to form regenerated ester flame retardant solution ;

(5) Screw extrusion and spinning--Rolling and spinning reaction of the recycled polyester flame retardant solution by using a wire drawing machine screw to produce a polyester flame retardant monofilament preliminary product;

(6) Cold and hot water drafting - polyester flame retardant monofilament first product is stretched into a specification wire by a series of cold water drawing, hot water drawing;

(7) High-temperature setting - the polyester flame-retardant monofilament first product is subjected to high-temperature setting;

(8) Warping - warping the polyester flame-retardant monofilament primary product by wire mesh warping machine to produce multi-strand polyester flame-retardant monofilament;

(9) Net machine molding - weaving polyester flame-retardant monofilament into a sheet of polyester flame-retardant dense mesh through a weaving machine:

(10) Cut piece - the piece of polyester flame-retardant dense mesh net is cut into a polyester flame-retardant dense mesh net according to the specifications by using a piece cutting machine;

(11) Sealing the mesh edge-polyester flame-retardant dense mesh net to seal the edge of the mesh by an edge banding machine;

(12) Finished product packaging - packaging the sealed polyester flame-retardant dense mesh into a shaft using a finished packaging machine;

The drying and dehydration time was 25 minutes. The flame retardant is a halogen-free environmentally-friendly reaction type long-lasting flame-retardant polymer flame retardant.

Copyright © HEBEI REKING WIRE MESH CO.,LTD. All Rights Reserved

Technical Support: