- Tel : + 86 311 85236281

- E-mail : alair@wirecloths.com

Title: Polyester Single Layer Forming Fabric

Key words: Polyester Forming Fabric

Single Layer Polyester Forming Fabric

Introduction:

According to the weaving type, Polyester forming fabrics can be divided into 4-shed, 5-shed, 8-shed, 16-shed,24-shed etc.

According to the category, it can be divided into single layer fabric, double layer fabric, two-and a half layer fabric and three-layer fabric.

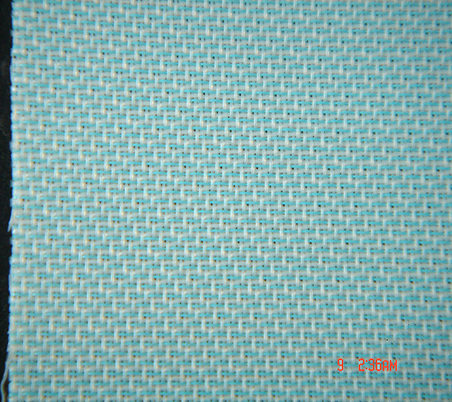

4-shed and 5-shed series single layer is standard type of polyester forming fabric in paper making, mainly used for producing cultural paper(single glue, double glue and color glue), Printing paper, glazed paper, packing paper, common newsprint and so on. Suitable for common fourdrinier paper machine.

8-shed single layer fabric is suitable for producing the packing paper which be requested with bag quantity, like kraft paper, cardboard, corrugated paper and so on. Also could be used for producing common printing paper. Suitable for common fourdrinier paper machine.

9-shed double layer fabric is suitable for producing quality printing paper which include dictionary paper, offset printing paper, newsprint and wrap paper. Also is could be used for producing tissue paper and the surface pulp, lining pulp, core pulp and bottom pulp of the board paper etc. Suitable for medium and high speed paper making machine.

16-shed double and a half layer fabric is suitable for producing quality printing paper, such as offset printing paper, copperplate paper, newsprint and cigarette paper series(wrap paper and filter tips paper), Also is could be used for producing toilet paper, tissue paper and surface pulp, lining pulp, core pulp and bottom pulp of board paper etc. Suitable for medium and high speed paper making machine.

Multi- shed three-layer fabric is suitable for producing quality printing paper, tissue paper and cigarette paper etc. Suitable for high speed paper making machine.

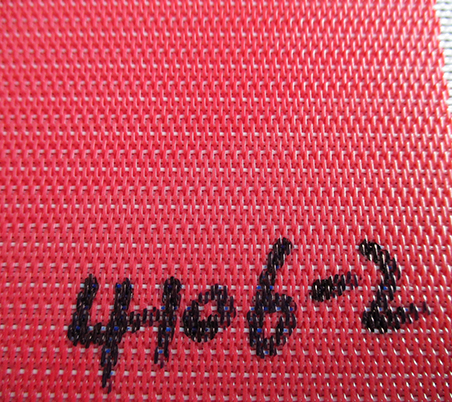

According to the category, polyester dryer fabrics can be divided into one and a half layer dryer fabric, double layer fabric, flat wire dryer fabric, flat double warp wire dryer fabric and special material dryer fabric.

3-shed, 4-shed one layer and a half are suitable for drying cultural paper, printing paper and packing paper etc.

Flat wire and flat double warp wire dryer fabric is suitable for the fore several heating box of the drying zone, quality papers can use the both.

Special material dryer fabric have the characteristics of high temperature resistance, abrasion resistance and aging resistance etc.

Weaving Series&Types | Model | Wire Diameter(mm) | Density (wire/cm) | Strength(N/cm) | Air permeability (m3/m2h) | ||

warp | weft | warp | weft | Area of the surface | |||

4-shed single layer fabric | 27254 | 0.2 | 0.25 | 29 | 22 | ≥600 | 7500 ±500 |

27274 | 0.2 | 0.27 | 30 | 22.5 | ≥600 | 7600±500 | |

31204 | 0.2 | 0.22 | 35 | 28 | ≥600 | 6500±500 | |

5-shed single layer fabric | 27255 | 0.2 | 0.25 | 30 | 23 | ≥600 | 7600±500 |

27285 | O.22 | 0.28 | 30 | 23 | ≥500 | 7800±500 | |

31205 | 0.2 | 0.21 | 35 | 32 | ≥600 | 6700±500 | |

8-shed single layer fabric | 25358 | 0.22 | 0.35 | 28 | 19.5 | ≥700 | 9000±500 |

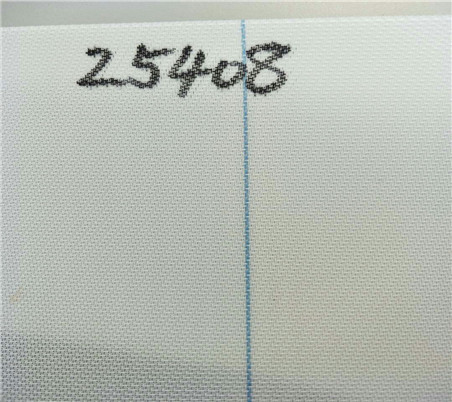

25408 | 0.22 | 0.4 | 29.5 | 19 | ≥700 | 8500±500 | |

27358 | 0.22 | 0.35 | 29 | 20 | ≥700 | 8500±500 | |

27408 | 0.22 | 0.4 | 31.5 | 19 | ≥700 | 8000±500 | |

8-shed double layer fabric | 56188 | 0.17 | 0.19/0.22 | 61.3 | 51.2 | ≥850 | 6800±500 |

60188 | 0.18 | 0.18/0.2 | 66 | 49 | ≥900 | 6000±500 | |

62188 | 0.15 | 0.16/0.17 | 70.5 | 50.5 | ≥900 | 5700±500 | |

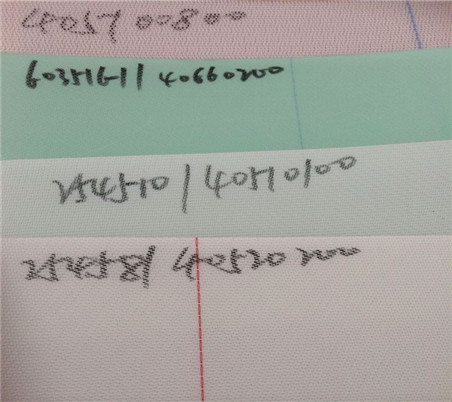

16-shed two and a half layer fabric | 365016 | 0.28 | 0.2, 0.27/0.5, 0.5 | 37-38 | 31-32 | ≥1200 | 8500±500 |

424516 | 0.25 | 0.2, 0.25/0.45, 0.45 | 48-49 | 42-43 | ≥1250 | 8000±500 | |

562516 | 0.18 | 0.13, 0.18/0.25, 0.25 | 57-58 | 46-47 | ≥1500 | 6500±500 | |

563516 | 0.2 | 0.13, 0.25/0.35, 0.35 | 56-57 | 61-62 | ≥1500 | 7000±500 | |

602516 | 0.18 | 0.13, 0.2/0.25, 0.25 | 62-63 | 55-56 | ≥1500 | 6200±500 | |

603516 | 0.2 | 0.13, 0.25/0.35, 0.35 | 61-62 | 52-53 | ≥1500 | 6300±500 | |

20-shed triple layer fabric | 563520 | 0.15, 0.2 | 0.15, 0.15/0.35, 0.35 | 70 | 55 | ≥1600 | 5000±500 |

24-shed triple layer fabric | 364024 | 0.2/0.2 | 0.2, 0.17/0.4, 0.4 | 42 | 52 | ≥1600 | 6500±500 |

Weaving series&Types | Model of Fabrics | Wire Diameter(mm) | Density(wire/cm) | Strength(N/cm) | Air permeability (m3/m2/h) | ||

Warp | Weft | Warp | Weft | Area of the surface | |||

3-shed series | 22503 | 0.5 | 0.5 | 24 | Weft | ≥2000 | 8000±500 |

4-shed series | 20504 | 0.5 | 0.5 | 22 | 12 | ≥1900 | 13000±500 |

22504 | 0.5 | 0.5 | 24 | 12 | ≥2000 | 12000±500 | |

24504 | 0.5 | 0.5 | 26 | 12 | ≥2100 | 11000±500 | |

Round wire fabric | 4106 | 0.5 | 0.5 | 22 | 12.4 | ≥2000 | 6800±500 |

Flat wire fabric | 4106-1 | 0.38*0.58 | 0.5 | 16.66 | 15 | ≥2000 | 5954±500 |

4106-2 | 0.38*0.58 | 0.4/0.6 | 18 | 14.66 | ≥2000 | 4800±500 | |

SL4106 | 0.5*0.75 | 0.6/0.,4 | 14.66 | 12.66 | ≥2100 | 6000±500 | |

SJ1860 | 0.25*1.05 | 0.6/0.9 | 9 | 7 | ≥2200 | 2100±500 | |

Packing Detail:

1.We always use poly bag for the goods which ship by air, so that customer can save freight free.

2.Wooden case is the best for ocean shipment, because it can effective avoid the damage during shipping.

3.There also have some customer request us to use the carton to packing their goods.

4.We can according to customer's requirement.

Q: How long is your delivery time?

A:Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q:Do you provide samples?

A:Yes, we can provide some of the product samples.

Its free and freight should be collected by your side.

Q:How can I know the completion of my order?

A:Deposit payment---start production---transfter infor to logistic---book shipment--inform customer ETD&ETA---load container---balance payment---send documents

Best Service:

1. Pre-sale service

Prompt,professional and patient reply;

Offer best quality products;

Recommend the most suitable products

2.After-sales Service

Timely tracking cargo transportation

Building customer files for regularly visit

Free replacement of damaged products

Deal with customers`dissatisfaction and complaints

Send gift to our customers

3.Customized packing is always welcomed

4.Assist to arrange transportation

Air Transportation,Sea Transportation

International Express :DHL,TNT,FedEx,UPS,EMS,ETC.

Copyright © HEBEI REKING WIRE MESH CO.,LTD. All Rights Reserved

Technical Support: