- Tel : +86-0311-85236281

- E-mail : sales@wirecloths.com sales4@wirecloths.com

Title: Stainless Steel Paper Making Cylinder Mesh

Key words: stainless steel mesh for pulp filtration

Description:

Stainless steel paper-making mesh is a woven mesh made of stainless steel wire, mainly used in the mesh part of paper-making machines to achieve the initial dehydration of pulp fibers to form wet paper sheets.

The Stainless Steel Paper Making Cylinder Mesh is a critical component in the paper manufacturing process. It is a precision-engineered, cylindrical sleeve made from high-grade stainless steel wires.

Its primary function is to act as a forming and drainage surface in the wet end of a paper machine. As the diluted pulp slurry is deposited onto the rotating cylinder mesh, water drains through its fine mesh openings, allowing the paper fibers to bond together and form a continuous wet paper web.

Feather:

Mesh count means the number of mesh holes per inch is usually used as the mesh number. The smaller the mesh number, the larger the mesh hole and the better the water filtration performance.

60~70 mesh stainless steel paper-making mesh is used for making newsprint and printing paper.

90~100 mesh stainless steel papermaking mesh is used for typing paper.

Advantages:

Exceptional Durability:** Resists corrosion, abrasion, and high tension, ensuring a long service life.

Precise Formation:** Provides excellent fiber support and drainage consistency for uniform paper sheet quality.

Low Maintenance:** Easy to clean and resistant to clogging, reducing downtime.

Hygienic: The non-porous stainless steel surface is ideal for hygienic paper grades.

It is widely used in the production of various paper and board grades, including tissue, fine paper, and specialty papers.

| Mesh Count | Warp wire diameter/mm | Weft wire diameter/mm | Warp:WeftMesh Count | Thickness/mm | Material |

| 8 mesh | 1 | 1 | 8 mesh:8 mesh | 2 | 304L/316L |

| 10 mesh | 0.6 | 0.6 | 10mesh:10mesh | 1.2 | 304L/316L |

| 12 mesh | 0.55 | 0.55 | 12mesh:12mesh | 1.1 | 304L/316L |

| 14 mesh | 0.5 | 0.5 | 14mesh:14mesh | 1 | 304L/316L |

| 20 mesh | 0.45 | 0.45 | 20mesh:20mesh | 0.9 | 304L/316L |

| 24 mesh | 0.45 | 0.45 | 24mesh:24mesh | 0.9 | 304L/316L |

| 30 mesh | 0.3 | 0.3 | 30mesh:30mesh | 0.6 | 304L/316L |

| 40 mesh | 0.28 | 0.3 | 40mesh:50mesh | 0.58 | 304L/316L |

| 50 mesh | 0.25 | 0.27 | 50mesh:60mesh | 0.54 | 304L/316L |

| 60 mesh | 0.24 | 0.24 | 60mesh:50mesh | 0.48 | 304L/316L |

| 70 mesh | 0.19 | 0.21 | 70mesh:60mesh | 0.4 | 304L/316L |

| 80 mesh | 0.19 | 0.19 | 80mesh:60mesh | 0.35 | 304L/316L |

| 90 mesh | 0.16 | 0.19 | 90mesh:60mesh | 0.35 | 304L/316L |

| 100 mesh | 0.14 | 0.15 | 100mesh:70mesh | 0.29 | 304L/316L |

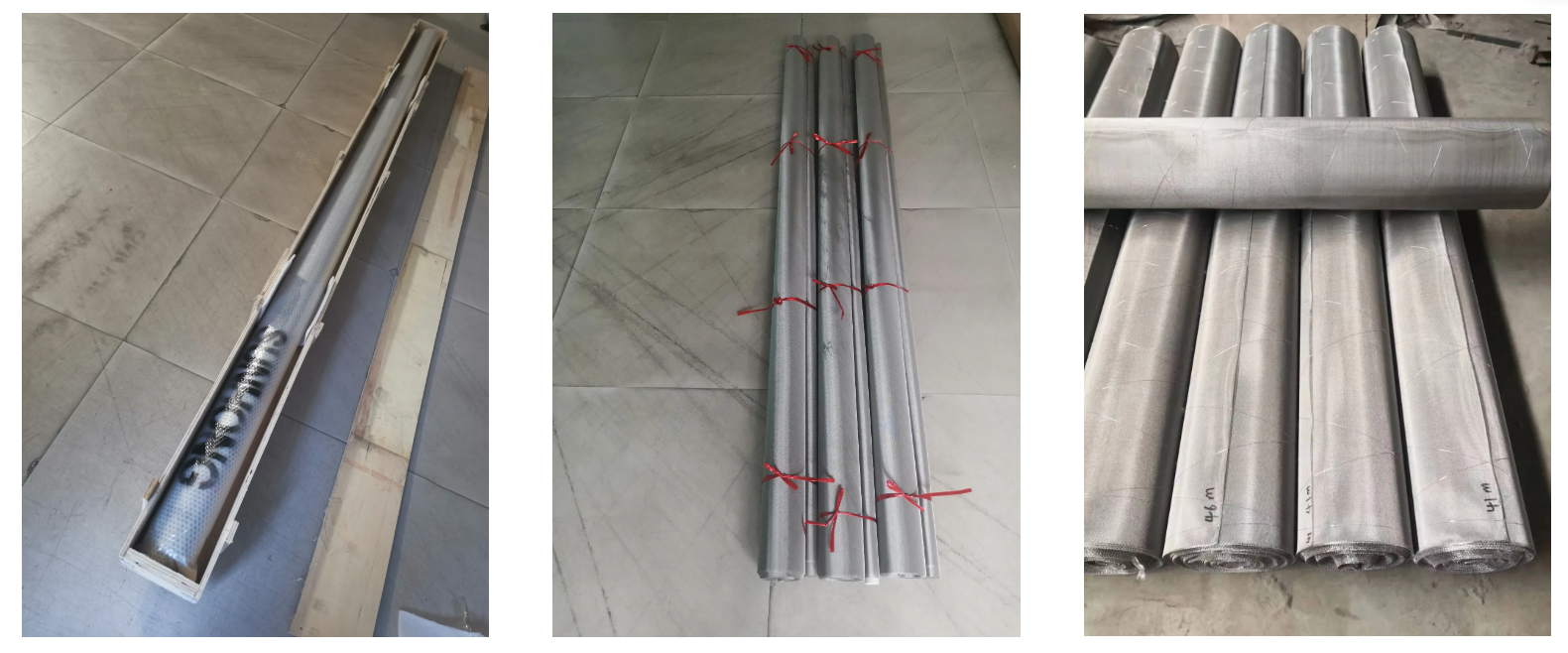

Packages:

1. Express delivery: Woven bags or cardboard boxes

2. Sea freight: Wooden crates or pallets

3. Packaging according to customer requirements

Shipping Way:

1.Express delivery

2.Sea freight

3.Air freight

Q: How is the mesh supplied?

A:The mesh can be supplied in roll form or cut pieces, with standard export packing to ensure safe transportation.

Q:How do I select the correct mesh for my application?

A:Please advise your application, required opening, working condition and temperature, and we will recommend a suitable mesh specification.

center

We’d love to hear from you!

Copyright © HEBEI REKING WIRE MESH CO.,LTD. All Rights Reserved

Technical Support: